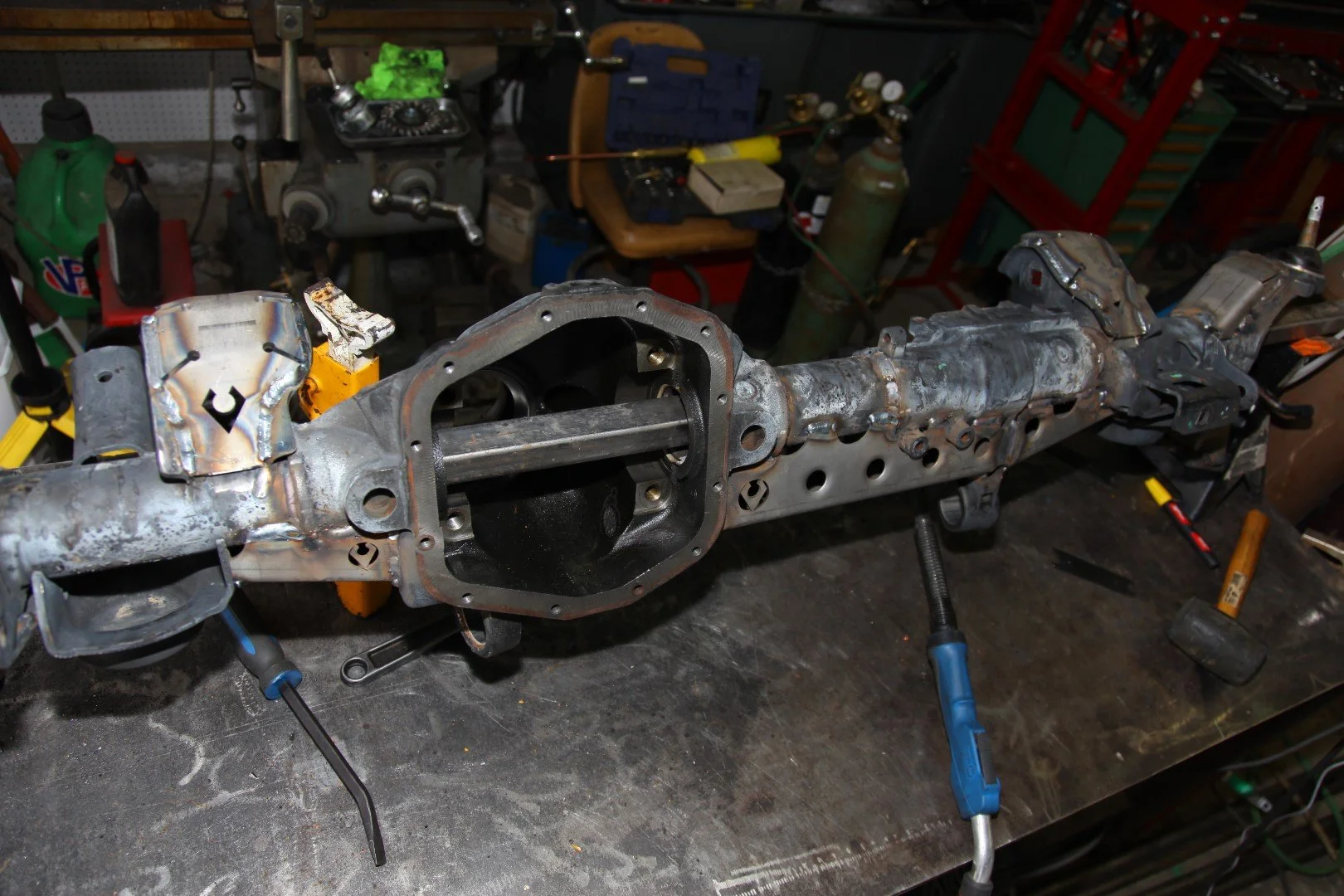

Dana 44 M210 Build

Today We start a short build series for the Dana M210 This axel is currently available in the following vehicles

2018+ | Jeep Wrangler JL Front – Rubicon – w/ Gas Engine

2020+ | Jeep Wrangler JL Front – Sport / Sport S / Sahara – w/Diesel Engine

2020+ | Jeep Gladiator JT Front – All Models

2021+ | Ford Bronco Front – Standard on Badlands, Wildtrak, 1st Edition & Squatch Pkg. (Option on other models) Note: Compatibility with New Bronco Axles Unconfirmed

The scope of work is as follows.

Completely strip the axel down.

Fit truss and armor

install new gear set and master kit

set up axel shafts and knuckles and brakes

I bought this axle a little over a year ago and it came with the housing, the e-locker, and the diff cover. I chased down the remainder of the part and I think I finally have almost everything to complete this axel.

After stripping the axle down I started with an Artec JK Apex Ultimate armor kit.

I sanded off paint everywhere I needed to weld. I started with the tubes as I plan to fully weld to the housing and the center axel disconnect. Many areas were easier to trace with a paint pen. The fitment of the parts was great, I don’t have to cut or bend anything. Everything just popped right into place!

Once everything was sanded down to bare metal everything was wiped down twice with Isopropyl Alcohol to ensure any contaminants are wiped away.

Next, we bring in some heat. I will be mig welding with a stainless steel wire while welding steel to ductal iron. I like to preheat to around 400F before I start welding. I try to heat as evenly as possible checking very often with an IR temperature gun. Reheats may be required while welding.

Then there is lots and lots of welding. All of the welds were roughly less than an inch long and I would start at one end of the axle and do one weld. Then move down the other end. Repeatedly going back and forth doing what I could by adding heat evenly to the axle while welding. Some of the welds were just steel on steel and not steel on ductal iron. So for those, I swapped the wire back to mild steel. after the welding was done I would just watch the axle with the IR gun and if one side of the weld was cooler than the other I would just add a little heat with a map gas torch. I would try to keep everything within 20 degrees.

After cooling the rest of the way down and an hour or so of wire wheel work and another wipe down of alcohol It’s looking pretty good in flat black.

I am quite pleased with how it came out overall. It’s a ton of work but the added strength is worth it. These axels are tough but I have heard of them bending and I’m planning on running 37” tall tires so we will be pushing this axel to it’s limits a little. I do offer the Artec truss here I am working with the supplier for the ultimate armor kit.

In the next part we are going to begin the assemble of the gear set and locker.